Purpose

This alert highlights the significant health risks caused by exposure to respirable crystalline silica (RCS) for workers in engineered stone benchtop manufacturing, finishing and installation industries.

Employers in these industries must ensure they are complying with their duties under the Work Health and Safety Act 2012 and have adequate dust controls in place. Failure to do so will result in enforcement action being taken.

Ongoing exposure to RCS can cause very serious and debilitating health effects, including silicosis. RCS is smaller than dust and can’t be seen. It is when these tiny dust particles (also called respirable dust) get deep into the lungs that the most damage is caused.

Background

Recent compliance audits of engineered stone benchtop manufacturers conducted in other Australian jurisdictions have identified multiple instances of workers being exposed to RCS. Health monitoring of these workers has returned multiple positive diagnoses of silicosis.

Contributing factors

Fabricating and installing natural and artificial stone bench tops can release high levels of RCS through cutting, grinding and polishing processes, particularly when dry cutting methods are used. Workers can also be exposed to RCS from poor cleaning practices, including dry brooming dust, using compressed air, using non-H class HEPA filtered vacuum cleaners, or allowing dust to accumulate within the workplace.

The risks are much greater when working with engineered stone, as it contains up to 95% crystalline silica, while natural stone contains 5-50%.

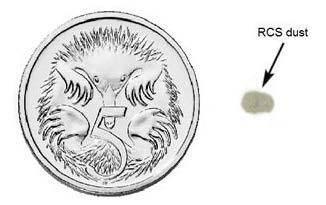

The workplace exposure standard for RCS will be exceeded if the amount of dust a worker breathes over a full shift contains more RCS than the amount shown here next to the five cent piece.

However, workers can still suffer adverse health effects from lower levels of exposure. There are three types of silicosis:

- acute silicosis is very rare and results from very short-term and very large amounts of exposure to silica (weeks or months)

- accelerated silicosis results from short-term large amounts of inadequately protected exposure to silica (5-10 years exposure). This was once rare, but is becoming more common in engineered stone workers and is the main reason for this alert

- chronic silicosis results from long-term exposure to low levels of silica (10+ years).

Once the opacities in the lung exceed 1cm in size, the disease is called Progressive Massive Fibrosis.

Action required

Immediately

Persons conducting a business or undertaking (PCBUs) must not allow uncontrolled dry cutting, grinding or polishing of artificial / engineered stone benchtops.

Engineering controls

- Water suppression of dust: For example, direct water feeds on cutting or grinding equipment, and sheet wetting using consistent and adequate water flows over the stone slab.

- Local exhaust ventilation (LEV):This includes only using cutting or grinding equipment when the LEV:

- is part of the equipment design

- is fitted to the individual equipment where dust is generated

- includes an H class dust collector or vacuum

- uses designed hoods or extraction machines.

Cleaning and maintenance of LEV fitted equipment must not expose workers to RCS.

- Wet dust slurry management: Wet spray must be controlled to prevent it becoming airborne. Spray can be controlled by using guards, plastic flaps and brush guarding. Wet waste, contaminated surfaces and contaminated garments must be effectively managed.

- Whole of workplace ventilation: For example, extraction systems. However, RCS must not be allowed to transfer from where it is generated.

- Cleaning: Workplaces must have a dedicated regular cleaning regime. Low pressure water, wet wiping or H class vacuums must be used. Dry sweeping methods must not be used. The cleaning must include areas where RCS can settle; for example, storerooms and yards.

Isolation

- Isolate processes and workers where RCS is generated or handled.

- Provide physical barriers between different work processes and work areas.

Substitution

- Use materials with no or lower percentage crystalline silica content.

- Use routers and water jet cutters instead of powered hand tools.

Health monitoring

PCBUs must provide health monitoring to workers when there is significant risk to a worker’s health because of exposure to a hazardous chemical such as RCS.

PCBUs must provide WorkSafe Tasmania with a copy of any health monitoring report as soon as practicable if the report:

- indicates a worker has contracted a disease, injury or illness (any reduction in lung function is considered an injury); or

- recommends remedial measures at the workplace.

Respiratory protective equipment (RPE)

Given that RCS is smaller than dust and easily inhalable, workers with a risk of exposure to RCS must be provided with appropriate RPE. Australian Standard AS 1715 provides guidance for respiratory protection and the use of RPE. A suitable RPE program will include:

- provision of suitable, comfortable RPE

- fit testing

- a maintenance and repair regime

- provision of information, training and guidance to workers.

RPE must be reasonably comfortable for the wearer. Consider providing powered air purifying respirators because of the physical demands of the task and potential for a hot and humid work environment.

Workers must wear the RPE whenever they are conducting dust-generating processes.

Information for workers

Workers must be given information, training and instruction about the:

- nature of the work carried out by the worker

- nature of the risks associated with the work and exposure to RCS

- control measures implemented at the workplace.

Consultation with workers

You must consult with your workers about minimising the risks associated with RCS and during the development of a health monitoring program, including the selection of the registered medical practitioner for health monitoring.

Consultation must meet the requirements set out in the Work Health and Safety Act 2012.

Resources

First published in November 2018